- Bommasandra, Bangalore, Karnataka

hpes_bg@yahoo.co.in

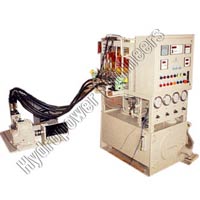

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Capacity | 600 Ton |

| Working pressure | 300 Bar |

| Stroke | 600mm |

| Click to view more | |

Product Details

The tube upsetting is the process of hot forge at the ends of the tubes. The upset increases the wall thickness to provide the machining stock and strength necessary for joining the tubes together. The dimensions of the upset ends for each tube differ based on the application and standard. The configuration of the tube end may be classified as external upset, internal upset and internal-external upset.Depending on the type of upset, the wall thickness may be increased by a maximum of 50% for external or internal-external upsets. It may be increased by a maximum of 100% for internal upsets. Depending on the limits, the upsets can be forged in one or two operations. Upsetting of tubes generates tremendous forces across the dies. The forge area on the tube upsets is normally about 3 to 10 times greater when compared to conventional forging machines. Our tube upsetting machine have substantially longer stroke, stock gather and hold-on. The available die length on our upsetting machine is considerably longer than that on a standard forging machine’s. Our Pipe Upset Induction Heating is an ideal technology for all your pipe upsetting needs. Induction heating provides rapid and even heating of tube ends for maximum upsetting quality.

- Application:

- Bore well industries

- Automobile industries

- Oil and gas industries

- Boiler industries

- Heavy engineering.